Some tips and tricks I've developed building and upgrading Crystal Palace, my Prusa i3 V2 3D printer clone.

Notes on the Reprap Guru Prusa i3 V2 3D Printer Clone

August 2017

Contents

In the summer of 2017 I bought and assembled a 3D printer kit from an outfit named Reprap Guru, which sells, among other things, clones of Prusa open-source designs. I would have happily bought from Prusa directly, but their top-of-the-line i3 V2 was back-ordered at the time, and I really needed a new printer quickly. This was a very cheap machine, and came with a certain number of problems, some expected, others surprising. This page exists to document my fixes for the benefit of any other owners of this machine (and so I don't forget things myself!), and is likely to be updated frequently for some time to come.

I named this printer Crystal Palace, in reference to its clear acrylic construction and in honor of one of the greatest feats of Victorian engineering.

Now this won't hurt a bit.

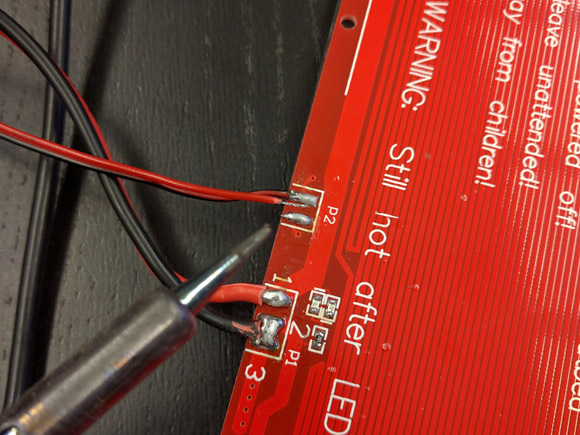

Fixing the Heated Bed

Right out of the box the thermistor on the heated bed PCB was shorted by a splash of solder, producing a MAXTEMP error in Repetier. The solder bridge was clearly visible with some magnification and was easy to clean up with a soldering iron.

About to resolder the broken thermistor wire.

After some running time I also experienced a failure of the thermistor wires where they join with the PCB; I fixed this by resoldering. Although without some method of strain relief for the y-axis wires I expect this will happen periodically.

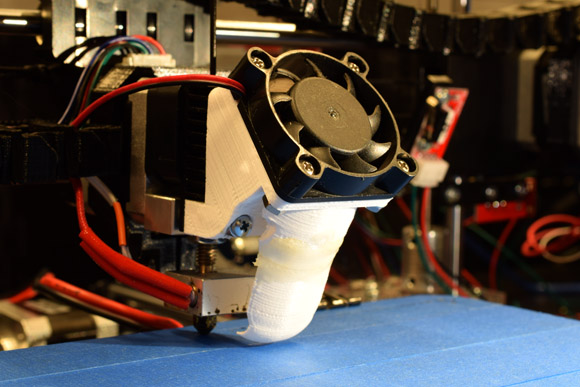

Cooling Nozzle

The small amount of epoxy visible in the photo fixes a crack caused by rough handling.

One of the first improvements I made to this machine was to print and install a cooling nozzle. This particular design, from thingiverse user James McGall diverts a small amount of cooling air from the extruder heat sink to the end of the nozzle. You can download the part at thingiverse or right here:

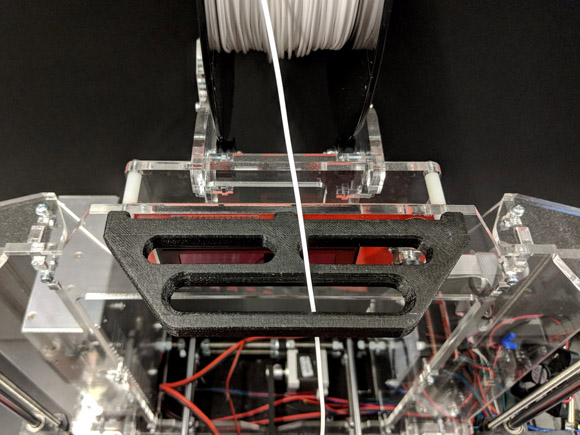

Filament Extender

Revision A.0, installed

I designed some guidance structures to keep the filament feed from the spool under control. These mount to the top-most two of the four screws in the control panel assembly; the original screws are just long enough to engage with the nuts when used this way. I've experimented with two designs. The first one, (rev 0.0), keeps the filament further out and prevents it rubbing on the x-axis cable chain but it puts a bit more load on the feed mechanism. The second one (rev A.0) allows the filament to travel quite a bit more along the x-axis to keep up with the extruder, but it does permit some interaction between filament and cable chain.

Revision 0.0

- Filament Guide, Revision A.0, Onshape document

- Filament Guide, Revision 0.0, STL

- Filament Guide, Revision A.0, STL

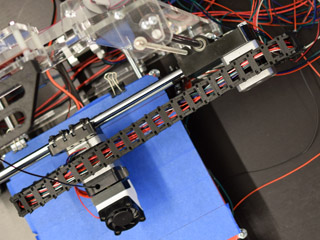

Cable Chain

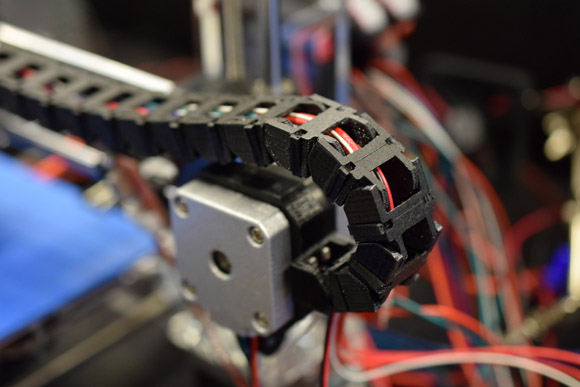

I've been steadily upgrading Crystal Palace by adding wire management, most importantly to wires that go to moving parts of the machine. For the x-axis I've adapted some cable chain parts from thingiverse; this version uses some snap-in cable retainers so that after assembling the chain, you can lay the entire cable bundle in the trough before snapping the retainers in place; this is much easier than feeding the end of the wire through.

X-axis cable chain.

I connected the x-axis cable chain from the x-axis stepper motor to the extruder stepper using two clamp-on adapters I designed. They use a 6-32 x 3/8 panhead machine screw and a 6-32 hex nut to provide the clamping force. The cable chain attaches to the adapter via a special male or female chain link that screws on with four #2 x 3/16 thread-forming screws.

- Cable chain x-axis adapters, Onshape document

- Cable chain link, STL

- Cable chain stepper motor adapter, STL

- Cable chain root link, female, STL

- Cable chain root link, male, STL

Upgrading the Linear Bearings and Rods

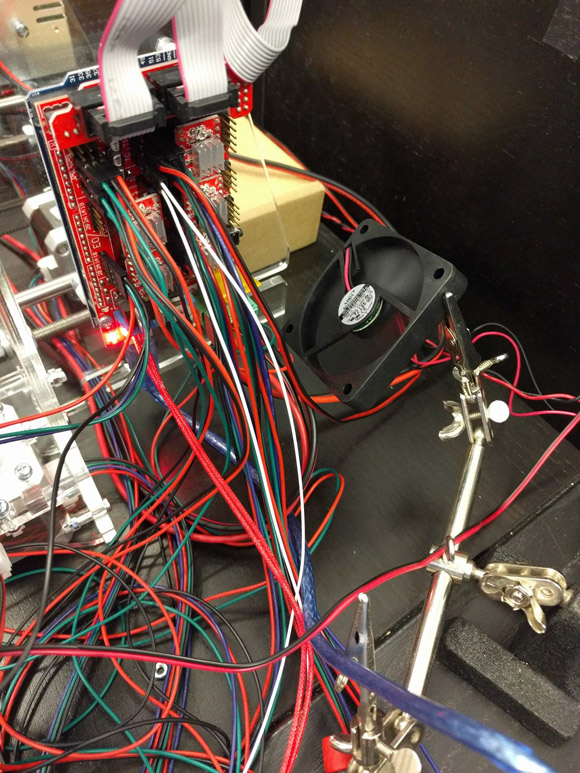

After not very many hours of operation at all I discovered that the printer was losing its position along the x axis multiple times during a typical print. At first I attributed this to insufficient current to the x-axis stepper and played with the potentiometer, trying to power my way out of the trouble. I also rigged a temporary cooling fan so that I could comfortably push the stepper drivers even harder.

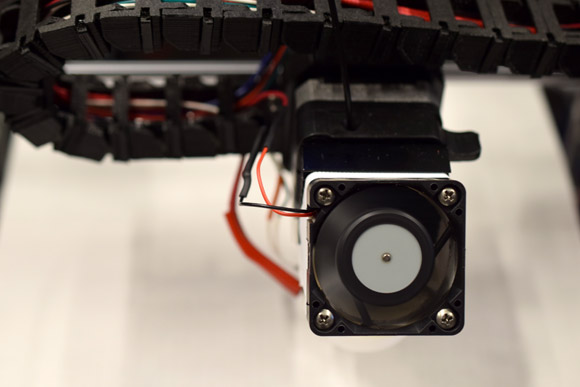

A fan kludge.

None of this really worked for long however, and I shortly discovered the real problem: there were noticeable grooves worn into the guide rods! This is down entirely to the low-quality parts shipped with the RepRap Guru kit; it turns out that the rods are ordinary non-hardened stainless steel and are quickly worn down by the hardened balls in the linear bearings. Those bearings aren't great either; a few balls escaped at the slightest provocation during assembly and the bearings never felt or sounded smooth, even when everything was brand new.

So I sprung for top-quality Misumi parts. All the rods and bearings are 8 mm diameter; the rods are 52100 bearing steel with a hard chrome finish. If you wish to replace all the components, you will need:

- 2x z-axis rods: 320mm long, Misumi #PSFJ8-320, $12.00 each.

- 2x x-axis rods: 365mm long, Misumi #PSFJ8-365, $12.00 each.

- 2x y-axis rods: 390mm long, Misumi #PSFJ8-365, $12.00 each.

- 10x linear bushings: 24mm long, Misumi #LMU-N8, $5.05 each at 10-19 units.

Replacing them is straightforward, just follow the Reprap Guru assembly instructions and these parts will fit just as the originals did. There is a night-and-day difference in smoothness however, as the next video shows.

MINTEMP Errors

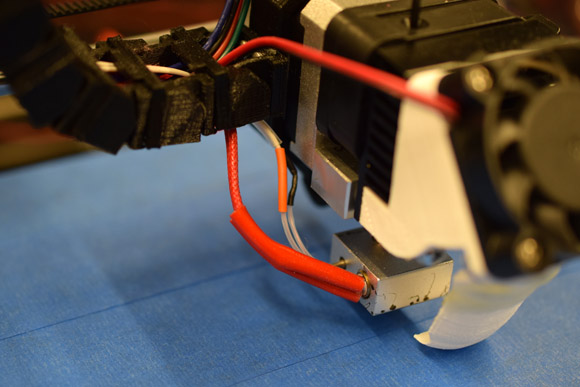

The extruder thermistor joints are sleeved in orange (original) and black (my fix).

After some more operating time, prints starting failing due to an intermittent MINTEMP error. I was seeing a lot of “cold extrusion prevented” errors in Repetier. After some research I discovered this was due to an intermittent connection to the thermistor wire at the extruder end. Fortunately I was able to resolder the joint without cutting or stripping any wire; the end that comes out of the extruder itself is very short and I don't want to have to make it any shorter.

Replacing the Extruder Fan

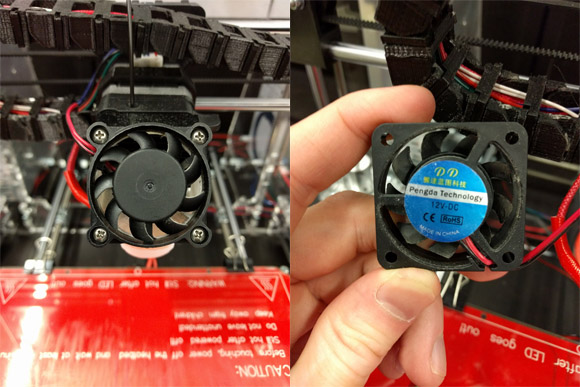

In December, after six months of fairly hard service, including leaving the printer running all night after completing a print on many occasions, the extruder fan became noticeably noisier. Tapping on the hub while it was rotating would quiet the fan briefly, but for a period of time that decreased the more I ran it. I expected this was due to bearing failure so I found some replacements.

Original fan as installed (left) and its hidden face (right)

Naturally the original fan was a cheap unit made in China by “Pengda Technologies”. Reprapguru.com sells replacements for only $3.99 with the following specifications claimed:

- Size: 40 x 40 x 10mm

- Voltage:12V

- Bearing: Sleeve/Dual-ball

- Airflow: 5.5 to 10.3CFM

- Speed: 5000 to 9000RPM

I don't know what a “sleeve/Dual-ball” bearing is but I suspect this term is marketing nonsense; I'd rather pay more for something that definitely has ball-bearings instead.

Two possibilities.

Searching at Mouser quickly yielded two suitable replacements: CUI's CFM-4010-13-10 and NMB Technologies' 1604KL-04W-B50-B00. I bought both but installed and am currently operating the NMB one; I'll update this page if I test the CUI product. So far the NMB fan is operating well.

NMB ball-bearing fan spinning.

Z-Axis Threaded Rod Replacement

During an un-attended zeroing of the z-axis one of the printer's loose wires got caught under the actuator of the z-axis limit switch, preventing the switch from closing. This meant that the z-axis stepper kept turning for minutes, causing the nuts on the lead screws to back out of the plastic housing, and giving me another reason, as though I needed another, to add cable-management features to the many wires that are still unsecured on this printer.

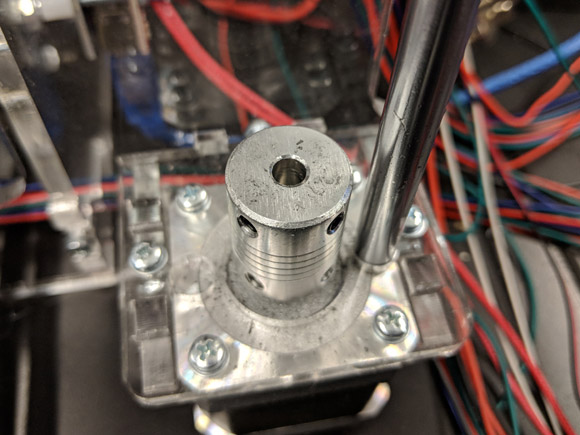

Plastic dust from the spinning nut on one of the couplers.

Although I reseated the nuts and leveled the printer again, I kept running into failures in which one side's z-axis mechanism would make a noise, and the bed would be out of level again. Turning the lead screw by hand felt crunchy and revealed many damaged areas of the thread. Also the area under the nut on that side was accumulating black plastic dust, as though the nut would turn in the housing when it encountered resistance.

For a simple solution I ordered new 316 stainless steel nuts (M5 x 0.8) and threaded rods (M5 x 0.8, 300 mm long) from McMaster-Carr. Although this wouldn't necessarily help if the plastic housing is very damaged and unable to hold a hex nut, it runs much smoother and so far I haven't encountered any more trouble; there must not be enough resistance to cause the nut to turn in the housing.

Y-Axis Stop Upgrade

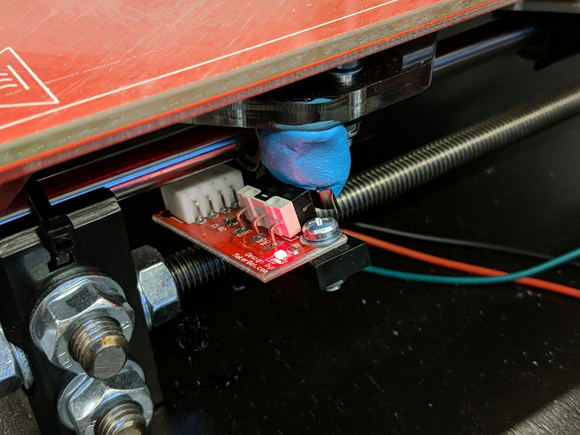

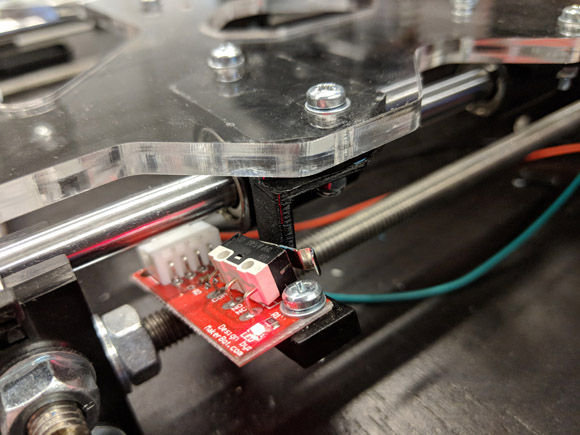

After a full year of merely managing the problem, I finally fixed one of the more irritating flaws in the printer. The designer intended the microswitch lever for the y-axis stop to be engaged by the edge of the y-axis bearing housing. But the housing doesn't extend far enough out to contact anything but the root of the lever, instead of the more effective far end of it, and to even achieve this you have to very precisely adjust the angle of the switch so that it's high enough to (barely) catch the edge of the bearing but not so high that the end of the lever catches the bottom of the bed leveling screw.

A tacky-looking fix.

In practice this balance wasn't easy to get right. Very often the switch would be able to stop the bearing mechanically without the switch actually closing electrically, so the stepper would skip and make noise until I'd rescue the printer by slapping the end of the lever myself. Or the bed leveling screw would trigger the switch and we'd be very far from the real zero position. For a while I stuck a wad of blu-tack putty under the bearing housing so that it could engage with the lever instead. This would work for a while until the blu-tack was mushed too far away and I'd have to reform it.

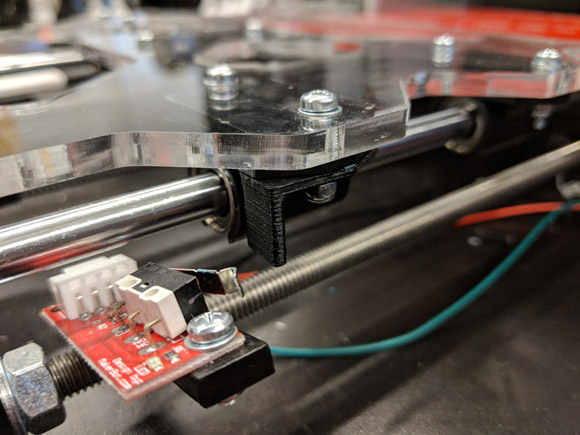

Right-angle bumper design, approaching the switch.

Success!

Once I decided to fix this problem seriously it only took about 40 minutes to get into Onshape, design something quickly, print it, and install it. Here are the links if you want to make one for your printer: