Welcome! I am an engineer, programmer, designer, and gentleman. You may be interested in some of my electrical and mechanical projects. Take everything you read here with a grain of salt and remember to wear your safety glasses.

Restoring a Steel Outdoor Table

Some years ago my mother found on the side of the road a small steel patio table, rusted, with original black paint in desperate condition. She brought it to my house, thinking that someday I might want to do something with it. Someday was last weekend.

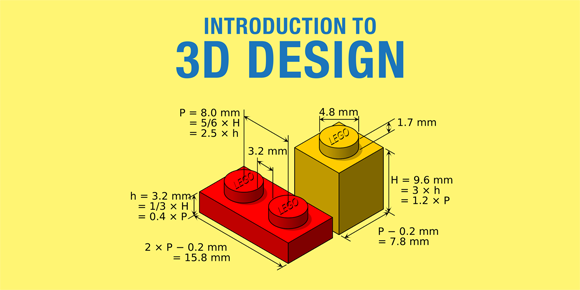

Introduction to 3D Design

Who wants to join me in the future? I'll be teaching an introductory CAD course at Hacklab North Boynton on Monday nights from 7 till 9. The price is $25 per session or $140 for all six. You'll learn to design your own parts suitable for 3d printing, machining, or any other process. All you need is a laptop and a mouse.

Our first session is this Monday, January 18th. We'll meet again on the 25th and on February 1st, 8th, 22nd, and 29th.

See you there!

Update, January 18: Hacklab North Boynton has postponed the future! But only by one week! Sign up and join me next Monday, January 25, instead. Thank you for your patience.

A Javascript Resistor Color Code Calculator

I recently built a small app that calculates a resistor's value based on color coding. This was an educational exercise in plain-vanilla javascript and old-fashioned html+css, although using jQuery would have saved me a lot of typing if nothing else. I tried to keep the color definitions and so forth as D.R.Y. as possible, going so far as to populate the select boxes from javascript using tedious DOM hacking. I'm sure many possible improvements will be immediately obvious to the attentive reader.

A Stainless Steel and Cedar House Number Plaque

Here's something I made recently. For many years my house number was marked by stainless steel numbers from Blomus that have bosses on the back so that they float off of the wall surface somewhat. When we painted the house gray the stainless just didn't have enough contrast against that background, and since I had done a gray-plus-wood sort of theme in the recent bathroom renovations I decided to extend this to the exterior of the house with a sort of wood plaque behind the house numbers.