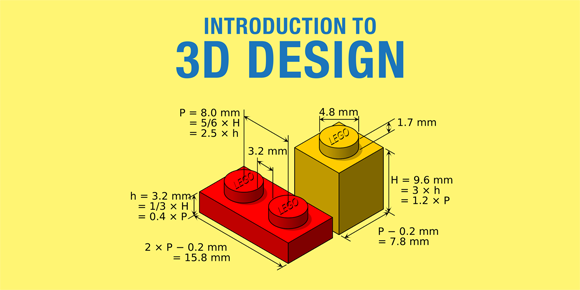

Introduction to 3D Design

Who wants to join me in the future? I'll be teaching an introductory CAD course at Hacklab North Boynton on Monday nights from 7 till 9. The price is $25 per session or $140 for all six. You'll learn to design your own parts suitable for 3d printing, machining, or any other process. All you need is a laptop and a mouse.

Our first session is this Monday, January 18th. We'll meet again on the 25th and on February 1st, 8th, 22nd, and 29th.

See you there!

Update, January 18: Hacklab North Boynton has postponed the future! But only by one week! Sign up and join me next Monday, January 25, instead. Thank you for your patience.